Cemented carbide, extensively recognized for its toughness and solidity, plays an important role across different sectors. Made up largely of tungsten carbide (WC) fragments adhered with a metal binder, such as cobalt, cemented carbide incorporates the toughness of tungsten with the durability of various other metals. The composition of cemented carbides can be tailored to fit particular applications, resulting in the production of selections like YG6, yg20, and yg15 tungsten carbide. YG6, for example, is understood for its high wear resistance and is frequently utilized in reducing tools and equipment where precision is critical. YG20 and YG15 tungsten carbide are used depending on the needed balance between solidity and strength, making them highly looked for after in numerous commercial circumstances.

In many sensible applications, carbides are created when metals like tungsten or titanium are incorporated with carbon, forming materials like tungsten carbide. Tungsten carbide itself is a dark gray to black, thick material that boasts remarkable hardness, ranking 2nd only to ruby in terms of material firmness.

One intriguing aspect of tungsten carbide is its development procedure, typically including sintering. Originally, tungsten powder and carbon are mixed with each other and warmed to a temperature high enough to speed up the development of tungsten carbide. The addition of cobalt or nickel offers as a binder to hold the tungsten carbide particles together, leading to a solid material that is both solid and resistant to abrasion. This procedure not only affects the density but also adds to the overall performance of the end product. The melting point of tungsten carbide is approximately 2,600 ° C(4,700 ° F ), making it suitable for high-temperature applications where conventional products would certainly fall short.

Tungsten carbide is commonly understood for its substantial industrial applications. From mining to manufacturing, the durability of tungsten carbide makes it ideal for creating wear parts that endure severe problems.

In addition, tungsten carbide plays an essential role in the production of specialized parts like blocks, tubes, plates, and rods. The adaptability of the material enables it to be fashioned right into numerous forms, providing to special industrial needs, consisting of cemented carbide buttons and bushings made use of in tooling applications. These elements improve performance and efficiency when machining various other products, making them indispensable in manufacturing procedures. Tungsten carbide EDM (Electrical Discharge Machining) blocks are commonly made use of for complex electrical discharge machining applications, where precision is of utmost relevance.

Recently, the appeal of tungsten carbide has actually surged in various other areas also, such as consumer products. Tungsten carbide rings, for instance, have actually gained nostalgic value as engagement and wedding event bands due to their sturdiness and scrape resistance. The material's ability to preserve a dazzling finish for longer durations than conventional rare-earth elements has actually made it a preferred option for lots of couples seeking resilient yet cosmetically pleasing options.

The manufacturing of tungsten carbide parts, such as saw tips, blades, and bushings, is considerable to industries that focus on both efficiency and high quality. In the world of building and mining, carbide saw tips are essential for tools used in puncturing hard products. Being wear-resistant and able to maintain sharpness longer than other materials, tungsten carbide saw tips are ideal for preserving performance and decreasing downtime during operations.

Furthermore, the improvement in cemented carbide manufacturing has enabled new innovations, such as the proposal for carbide blocks, strips, and preforms that accommodate highly certain applications. Businesses depend on personalized carbide preforms, which are manufactured to fit one-of-a-kind specifications, guaranteeing that the end product carries out efficiently in its intended application. The rise of manufacturers creating carbide blanks and strips has actually also altered the marketplace dynamics, offering customers with more choices customized to their specific requirements.

The comparison between carbide and tungsten carbide exposes some essential differences. While carbide can refer to any kind of carbon compound with a metal, tungsten click here carbide definitely denotes the mix of tungsten with carbon.

Aside from tungsten carbide, an additional pertinent material in the conversation of hard steels is Stellite, frequently known for its excellent wear resistance and heat resistance in challenging atmospheres. Stellite, a cobalt-chromium alloy, is often utilized in applications where both thermal and wear resistance are essential. Stellite 6 and Stellite 6B variants offer special functions in sectors where devices encounter severe conditions. The main distinction hinges on the composition of the alloys and their respective resistance to warmth and abrasion. While tungsten carbide masters hardness, Stellite materials are frequently liked for applications needing both strength and resistance to ecological variables.

As sectors constantly seek products that can give toughness and precision, cemented tungsten carbide stays a preferred choice. The combination of high wear resistance, sturdiness, and thermal stability has maintained tungsten carbide's standing at the center of industrial products. The presence of different qualities, such as YG20, yg6, and yg15, guarantees that engineers and manufacturers can pick appropriate options tailored to specific efficiency demands. Furthermore, in comparison to other products, particularly high-speed steel or typical steel, tungsten carbide stands for a substantial improvement in machining innovation, offering improved performance via faster machining speeds and expanded device life.

Tungsten carbide additionally has a remarkable presence in the jewelry sector. Its distinct residential or commercial properties, such as scrape resistance and high luster, have actually made it a significantly prominent choice for wedding bands and various other fashion accessories. The capacity to accomplish a refined coating combined with its enduring nature enables tungsten carbide jewelry to maintain its aesthetic charm in time. This crossover from industrial use to personal things exemplifies the flexibility of tungsten carbide across numerous market sectors.

In regards to its thermal buildings, tungsten carbide has a high melting point, generally around 2,870 levels Celsius (5,200 levels Fahrenheit), which gives outstanding security in high-temperature applications. Such thermal stability makes tungsten carbide an outstanding candidate for cutting and machining operations that experience boosted rubbing and warmth. Its ability to sustain tension and warmth without warping further enhances its worth in settings where standard tools may stop working.

The continuous r & d in carbide innovation promise to unveil much more applications and enhancements for products like tungsten carbide, leading to developments that could reshape making processes. The future of cemented carbides looks appealing as markets remain to identify special options while leveraging existing products. Eventually, as the need for long lasting, high-performance materials grows, tungsten carbide and its different kinds will likely continue to be at the leading edge read more of material scientific research and engineering, driving requirements for performance and effectiveness in manufacturing and beyond. In conclusion, tungsten carbide's complex applications, from accuracy devices to decorative uses, illustrate its exceptional versatility and toughness, making it an essential material in both industrial and industrial contexts. Due to its combination of properties such as density, solidity, and thermal stability, tungsten carbide is expected to control numerous areas for many years ahead.

In summary, tungsten carbide and cemented carbide are keystones in the market, reflecting the developments in material science and design. The many applications ranging from tools and wear elements to customer products demonstrate their relevance in everyday life. With recurring r & d, the landscape for tungsten carbide remains to advance, going after new applications and developments that broaden its reach. As industries around the globe proceed to demand effectiveness and longevity, materials like tungsten carbide and its numerous types will certainly continue to be central to meeting these demands. The importance of comprehending the one-of-a-kind homes and applications of these hard metals can not be understated, as they proceed to change sectors and boost productivity throughout the board.

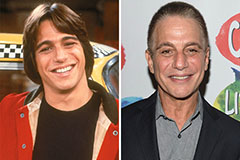

Tony Danza Then & Now!

Tony Danza Then & Now! Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now!